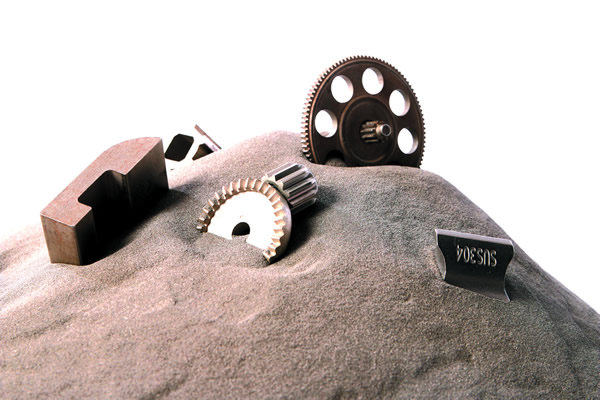

Your Location: Home » Products > Stainless Steel Powder For Sintering Parts

Products

Give me a message

Technical Parameters

| Austenitic Stainless Steel | Ferritic Stainless Steel | Ferritc/Martensite Stainless Steel | |||||||

| 304L | 303L | 316L | 409LE | 434L | 410L | ||||

| Powder Properties | |||||||||

| Apparent Density, g/cm3 | 2.85 | 2.90 | 2.75 | 2.70 | 2.72 | 2.70 | |||

| Flow Rate, s/50g | 28 | 27 | 32 | 34 | 34 | 34 | |||

| Chemical Compositions | |||||||||

| C, % | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | |||

| Ni, % | 9.5 | 10.2 | 12.8 | ||||||

| Fe, % | Balance | Balance | Balance | Balance | Balance | Balance | |||

| Cr, % | 19 | 19.5 | 18 | 12 | 16.8 | 12.5 | |||

| Si, % | 0.9 | 0.9 | 0.8 | 0.8 | 0.8 | 0.8 | |||

| O, % | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |||

| N, % | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | |||

| Mo, % | 2.5 | 1.0 | |||||||

| Nb, % | 0.5 | ||||||||

| Sieving (µm ) | |||||||||

| +150, % | 0.8 | 0.8 | 1 | 0.9 | 0.9 | 0.9 | |||

| -45, % | 43 | 40 | 41 | 45 | 42 | 42 | |||

| The Green Properties | |||||||||

| GD 600 MPa g/cm3 The Green Density with Lubricant |

6.45 | 6.4 | 6.5 | 6.45 | 6.45 | 6.45 | |||

| GS 600 MPa, Mpa The Green Strength with Lubricant |

7.5 | 7.1 | 8.5 | 14 | 12 | 13 | |||

| Lubricant = 1% Acrawax | |||||||||

| Sintering Temperature | 1150° C | 1250° C | 1150° C | 1250° C | 1150° C | 1250° C | 1250° C | 1250° C | 1250° C |

| Sintering Density, g/cm3 | 6.7 | 6.78 | 6.68 | 6.75 | 6.85 | 6.92 | 6.9 | 6.9 | 7.02 |

| Performance and Application Examples | - Excellent Corrosion Resistance - Non-Magnetic - Application is suitable for the production of locks and home appliance parts. |

Free processing of Austenitic Stainless Steel | - Corrosion resistance is extremely high, especialy suitable for chlorine ion solution - Non-Magnetic - Often used in the production of stainless steel powder metallurgy parts in different areas, such as small gear, cam and linker |

- Medium Corrosion Resistance - Ferromagnetic - Suitable for welding - Suitable for the production of automobile exhaust flage and hot exhaust gas oxygen sensor hubparts |

- Medium Corrosion Resistance and higher than 400 series - Excellent magnetic property - Suitable for the production of automobile exhaust flange parts |

- Medium Corrosion Resistance - Ferromagnetism - Suitable for the production of sensor circle parts of ABS system - Graphite can be added ( to increase hardness and abrasion performance) 410/420 Convert into Martensite Stainless Steel 410/420 |

|||

Send your message to us

Latest News

READ MOREIdeas on how to improve our website?

CONTACT US