3D print manufacturing is a revolution in manufacturing mode". 3D printing as a new process, will change the way to mass production assembly line as the representative of the second industrial revolution is produced, the product production shift to personalized and customized, realize the transformation of the mode of production. Application of 3D printer will reduce the time to market the product, the user simply download the design in a few hours by 3D printing products will be "printed", which does not require large-scale production line, do not need a large number of spare parts inventory, do not need a lot of workers.

1, 3D printing technology

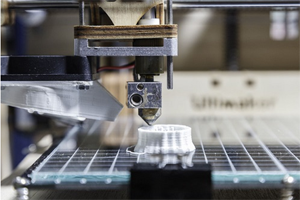

3D printer was born in the middle of 1980s, the use of 3D printing technology to produce a device 3-D object, its basic principle is to use a special

material (glue, resin or powder etc.) by the computer in accordance with the pre designed three-dimensional model, by depositing adhesive will each layer of powder molding, the final print 3D entity. 3D printing process can be divided into two steps, first spray the special glue in forming area, and then evenly sprayed powder, powder curing glue will meet quickly, no glue area still maintain a loose state, this process is repeated until a solid model is the "print" type. Because the process is very similar to the ink jet printer, it is called "printing technology" ".

2, 3D printing technology in the future

In the next 5-10 years, with the continuous progress of technology and the expansion of market demand, 3D printers will present three trends: first, the speed and efficiency of 3D printing will continue to improve. With the development of parallel, multi material manufacturing process, the printing speed and efficiency is expected to get a greater upgrade; two is the 3D printing material is more diversified. With the continuous development of advanced materials, smart materials, nano materials, new polymeric materials, synthetic materials and other materials will become 3D printing materials; three is a significant decline in the price of 3D printers. Some smaller 3D printer manufacturers have started to roll out $ten thousand below the 3D printer. With the technical progress and popularization and application, the price of 3D printers is expected to drop significantly. Four is the 3D printer application areas more widely. 3D printer was born, mainly used in aerospace, machinery, medical, construction and other industries model production. As its further mature, 3D printers have begun to manufacture automotive, aircraft and other high-tech content components, skin, bone and other living tissue. Experts predict that in the near future, from shoes, glasses to the kitchen appliances, cars and other products can be produced with a 3D printer.

Daye metal powder factory production of 3D printing with stainless steel powder oxygen content less than 200PPM, similar to the spherical surface, with good mechanical properties, has a wide range of applications in the field of

3D printing.